By David Calvert, June 2017

It has been a strange last couple of years in global politics, and while the question “just what on Earth is going on?” may have been used in relation to Brexit, the US election, the latest UK election or Leicester City winning the English Premier League, it is still a question which as formulators we continue to ask ourselves. Whether it be changing viscosity, phase separation, product crystallising out or the product simply not working, the answer can often be found in a poorly thought out, or rushed, formulation design.

The solution to this often lies in using a formalised design process for the formulation which starts well before you actually commence your practical work. A quantified definition of what you are actually promising your customer, the competitive IP situation and essential cost and regulatory constraints are among the factors you need to consider at the onset.

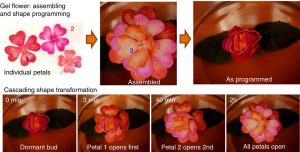

Following this initial, essential preparation you commence your laboratory work where you are likely to need an experimental design approach in order to flush out the key components of your formulation, including almost certainly interactions between components. You will also need to define a preliminary manufacturing process, similarly with a definition of its key elements.

With a good laboratory programme behind you, you move to pilot stage, where you encounter scale-up issues such as mixing, heat transfer, dead-spots, cleaning and avoidance of contamination. You may have already sampled a customer with your product and could widen your product sampling at this stage.

If all progresses well, then the transfer to manufacture occurs. Ideally you will have consulted with your manufacturing colleagues well before this stage, rather than this being the first time they have heard they need a novel mixer, or a large scale “spatula”. Here you will understand what are the critical elements of the process are and what control strategies you envisage.

With successful manufacture, you then reap the benefits of all the hard work and can use the knowledge gained to go forward and develop your next range of products.

Risk assessments form an essential element of the “stage-gate” type approach to development that you will need to take. As you move through the process and the risks should be better defined and reduced, the closer you get to production and commercialisation.

We call this systematic approach “Design for Formulation” and if you want to learn more, we are running a two day training workshop at Jury’s Inn Hotel, East Midlands Airport, in the UK on September 19th and 20th. You will hear from experienced practitioners such as our Associate Partner Ian Jolliffe, David Hood from the Excellence Partnership, Phil Threlfall-Holmes of TH Collaborative Innovation (THCi) and Olivier Cloarec of Sartorius-Stedim.

There are two webinars available where you can hear David and Ian talk about different elements of the process. Follow the links below – and send an e-mail to info@iformulate.biz if you require passwords.

– iFormulate introduces…Ian Jolliffe on “Design for Formulation”

– iFormulate introduces…Process Control and Formulation

Details about the course and how to register before the August 1st early bird deadline can be found on the event web page.